Customized Post Tensioning Wedge

The post tensioning wedge is a crucial component used in prestressed concrete structures. By applying prestressing force on the concrete elements, it significantly enhances the load-bearing capacity and durability of the structure.

Product Description

The post-tensioning wedge is a crucial component used in prestressed concrete structures. By applying prestressing force on the concrete elements, it significantly enhances the load-bearing capacity and durability of the structure.

In order to meet different requirements of our customers and as we have R&D team to develop, RuiYi provides many Customized Post Tensioning Wedge to our customers.

For example, if you have only an idea of the diameter of the PC strand, we could provide you professional advice and drawings of anchor and wedge that could be workable for your confirmation.

If you have drawings, RuiYi could provide OEM service for your products with good quality control and reasonable cost.

If you have real samples, an equal sample could be made for your confirmation.

The customization process usually is: Primary communication-drawings produce-drawings confirmation-sample production-sample confirmation-production and there will be certain sample cost according to the difficulty of making.

|

|

|

|

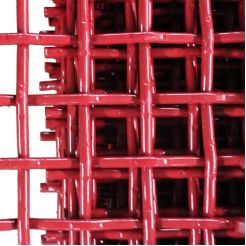

| RYM13 Customized | RYM13 Custom Thread Pitch | RYM13 Clamp (12.7x35.8mm) Custom Shape | RYM13 clamp customized shape |

Production Process of Post Tensioning System

The wedge production includes 8 parts, which are:

● Cutting-raw material 20CrMnTi Bars are cut into small pillars as required.

● Forging-After cutting, it will be punched central holes by CNC forging machine.

● Engraving-After forging, it will be cut to required size and angle by CNC engraving machines.

● Tapping-after engraving, it will be tapped to certain thread shape and size as required.

● Splitting-After tapping, it will be cut into 3 or 2 pcs as required.

● Heat Treatment-After splitting, it will be heat treatment at 890℃.

● Assembling-After treatment, it will be inspected and assembled by auto machine.

● Packing-Finally, it will be packed into box or bucket as per requirements.