Stainless steel tank fit-up plasma welding center

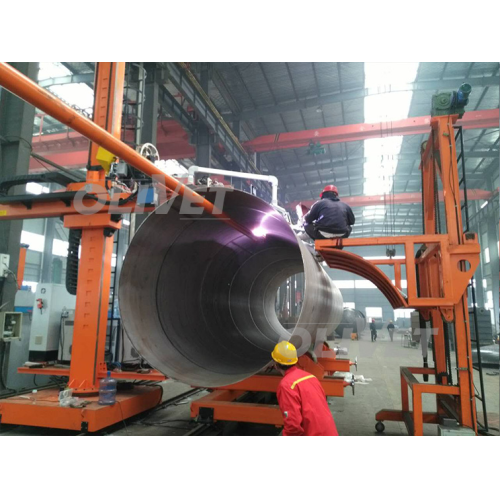

The plasma and tig welding center( plasma welding center, stainless steel tank welding, stainless steel pipe welding center ) is developed for a high quality welding requests on longitudinal seam and circular seam of stainless steel tanks and pipes.

Product Description

The plasma and tig welding center is developed for a high qulity welding requests on longitudinal seam and circular seam of stainless steel. The welding center is widely used for food industry, pharmaceutical indusry and other stainless steel shell production industry.

Double avc (arc length auto control system) and plc programe system equipped to ensure the welding center is advanced and stability to finish shells with good welding qulity.

The Plasma welding center inculds two staions, single section longitudinal seam welding and many sections fit-up circular seam welding.

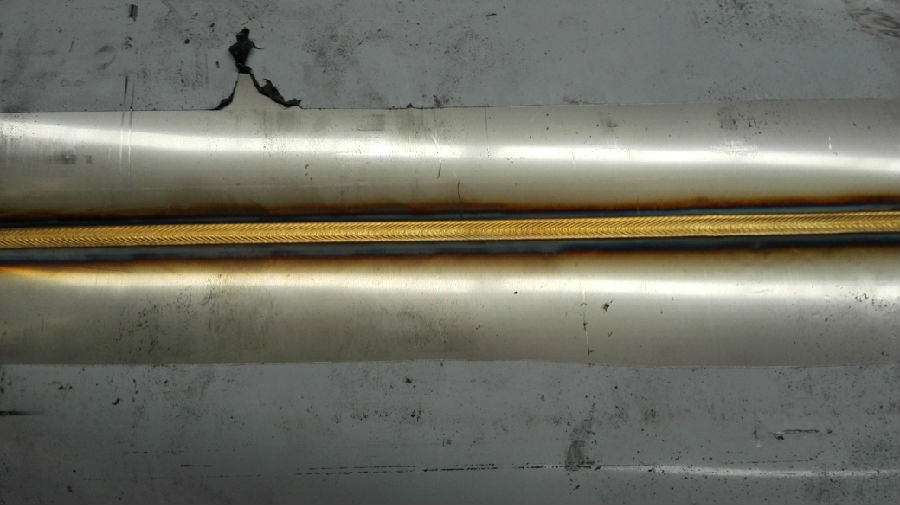

The Plasma welding center can finish the longitudinal and cirular seam welding of stainless steel at one pass under thickness of 3mm to 10mm without beveling processing.

The plama welding center can greatly improve the welding speed and save much labor cost.

1. Welding system

|

PLA-WEL501D plasma welding source (chopped mode) |

|

|

Brand |

Taiwan tpc |

|

Impulse frequencey |

1-500hz |

|

Max welding currant |

500a |

|

Max duty cycle |

100% |

|

Current consumption at 100% duty cycle |

33.8a |

|

Power consumption at 100% duty cycle |

24kva |

|

Volage/ currant display |

Digital |

|

Control operating |

Plc touch screen |

|

Plate thickness |

3-10mm |

|

PLA-TIG501D plasma welding source (chopped mode) |

|

|

Brand |

Taiwan tpc |

|

Impulse frequencey |

1-500hz |

|

Max welding currant |

500a |

|

Max duty cycle |

100% |

|

Volage/ currant display |

Digital |

|

Control operating |

Plc touch screen |

|

Atomatically wire feeding system |

|

|

Drive mode |

Four wheel |

|

Feeding speed |

0-10m/min |

|

Speed control accurancy |

±1% |

|

Steel wire diameter |

?1.0-1.2mm, ?0.8-1.6mm |

|

Aluminum wire diameter |

?1.2-1.6mm |

|

Feeding control |

Closed-loop feedback and program |

2. Electrical control system

The automation control system adopts mitsubishi plc control. Vfd and relays are from schneider, which are reliable performance.

Taida 5.6 inch color touch screen displays operaton and running information. Data communication via optical cable to ensure the data accuation.

3. Welding Equipments

4. Finished tanks