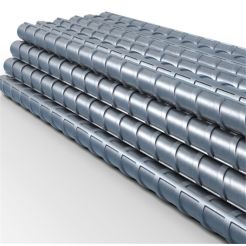

Aluminium Foil Air Conditioner Fin Stock

Air conditioner aluminium foil, radiator aluminium foil is our star product. Used for aluminum foil production of heat transfer fins for air conditioning heat exchangers Classification, Editing and Broadcasting of Aluminum Foil for Air Conditioning

Product Description

Air conditioner aluminium foil, radiator aluminium foil is our star product. Used for aluminum foil production of heat transfer fins for air conditioning heat exchangers

Classification, Editing and Broadcasting of Aluminum Foil for Air Conditioning

Aluminum is widely used due to its advantages such as low density, good thermal conductivity, ease of processing, odorlessness, environmental protection, and low price. The use of aluminum foil to make heat transfer fins for air conditioning heat exchangers is a representative of this. Aluminum foil has been widely used in the production of air conditioning heat exchangers for more than 20 years in China, and has achieved rapid development in the past 10 years. With the development of China's economy and the continuous improvement of people's living standards, the popularity of air conditioning has been increasing year by year.

According to different thicknesses, it can be divided into thin plates and medium thick plates. Aluminum foil with a thickness of less than 0.2 millimeters is specified in the GB/T3880-2006 standard.

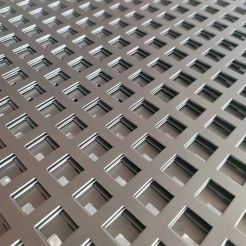

Air conditioning is gradually developing towards miniaturization, high efficiency, and long lifespan. And the air conditioning heat exchanger is also developing towards ultra-thin and high-strength direction. In the 1980s, the thickness of the heat exchanger was 0.15-0.2ram, while today's thickness is only between 0.09 and 0.15mm. In addition, in order to improve the lifespan of air conditioners, reduce power consumption, improve ventilation quality, and improve refrigeration efficiency, coating heat exchangers with various functions have been developed successively. Typical ones include anti-corrosion heat exchangers, surface hydrophilic heat exchangers, surface hydrophobic heat exchangers, mold resistant heat exchangers, and self-lubricating heat exchangers.

Classification:

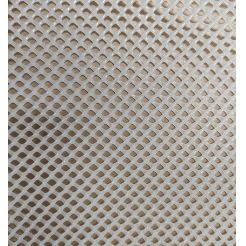

1. Uncoated aluminum foil

Non coated aluminum foil refers to aluminum foil that has been rolled and annealed without any form of surface treatment. Ten years ago in China, about 15 years ago in foreign countries, the aluminum foil used for air conditioning heat exchangers was all uncoated aluminum foil. About 50% of the heat exchangers used in developed countries abroad are still uncoated aluminum foil, while in China, this ratio is around 60%.

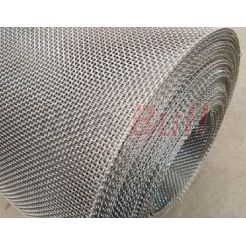

2. Coated aluminum foil

The so-called coated aluminum foil refers to the surface treatment of uncoated aluminum foil to give it a certain special function. In countries with rapid technological development such as Japan and Germany, the use of coated aluminum foil has a history of over 15 years. In China, the use of coated aluminum foil does not exceed 10 years. According to the characteristics of the surface of coated aluminum foil, it can also be classified as follows:

3. Corrosion resistant aluminum foil

The surface of corrosion-resistant aluminum foil products has a certain anti-corrosion protective layer, and the air conditioning heat exchanger made of this product can be suitable for harsh areas and significantly improve the service life of air conditioning. Meanwhile, due to the improved corrosion resistance of the heat exchanger, the generation of surface corrosion powder is greatly reduced, thereby improving ventilation quality and purifying the air inside the air conditioning room.

4. Hydrophilic aluminum foil

The surface of hydrophilic aluminum foil has strong hydrophilicity. The hydrophilicity is determined by the angle formed by water adhering to the surface of aluminum foil. The smaller the angle, the better the hydrophilicity, while the opposite results in poorer hydrophilicity. Generally speaking, the angle a is less than 35. It belongs to hydrophilic properties. Hydrophilic aluminum foil is generally used on evaporators of air conditioners. Its main function is to make the moisture in the hot air condense into water droplets on the heat exchange plate, which are easy to spread and flow down the plate. This can avoid affecting the ventilation effect of the heat exchanger due to the "bridging" of water droplets between the heat exchange plates, thereby improving the heat exchange rate of the air conditioner, and saving electricity under the same cooling capacity conditions. Previously, the general hydrophilic aluminum foil on the market not only had good surface hydrophilicity, but also had high corrosion resistance, thereby optimizing the performance of air conditioning.

5. Hydrophobic aluminum foil

Hydrophobic aluminum foil, also known as hydrophobic aluminum foil, has the opposite surface properties as hydrophilic aluminum foil. When the condensed water condenses onto the surface of the aluminum foil, the contact angle with the aluminum foil is relatively large, usually around 75. Above. The larger the angle, the better the water repellency. The ultimate purpose of using hydrophobic aluminum foil is the same as that of hydrophilic aluminum foil, that is, to prevent condensation water from staying between the heat exchanger plates. The difference is that hydrophobic aluminum foil achieves the purpose of removing condensation water between heat exchangers by increasing the contact angle between the condensation water and the heat exchanger, causing the condensation water to form water droplets that are easy to slip off.

6. Self lubricating aluminum foil

In the process of processing and manufacturing, the heat exchanger of air conditioner generally needs to add lubricating oil on its surface, then punch and flan, and finally use Trichloroethylene to wash off the lubricating oil. Since Trichloroethylene is harmful to human body, self lubricating aluminum foil is produced to reduce this process. As the name suggests, self-lubricating aluminum foil does not need to be lubricated separately during its stamping process. The lubrication during stamping is borne by the pre treated film on the surface of the aluminum foil. Since no special lubricating oil is required, subsequent Trichloroethylene cleaning and drying processes are also omitted.

7. Mouldproof aluminum foil

Mouldproof aluminum foil is mainly used for indoor units of air conditioning, and its main function is to prevent the surface of the heat exchanger from becoming moldy due to long use or storage time, thereby significantly improving the ventilation quality of air conditioning, preventing abnormal odors, and effectively improving the indoor environment of air conditioning.