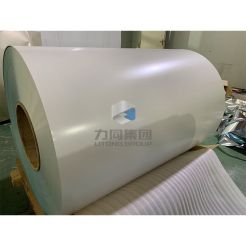

color coated aluminum coil

Product Description

https://www.ltcoatingcoil.com/productstags/color-coated-aluminum-coil.html

Color coated aluminum coil is the surface coating of aluminum plate coloring treatment. Common fluorocarbon color-coated aluminum and polyester color-coated aluminum are widely used in aluminum-plastic panels, aluminum veneers, aluminum honeycomb panels, aluminum ceilings, roofs, corners, Easy-open cans, electronic products. Its performance is very stable, it is not easy to be corroded, the surface can be guaranteed for 30 years after special treatment, the unit volume weight is the lightest metal material, and the color-coated aluminum coil is the most popular new material. Color-coated aluminum coil has rich colors, whether it is a residence, a large commercial outlet or a large exhibition center, it can add color. Good plasticity and machinability make it an ideal material for various architectural shapes. It provides architects, designers and homeowners with a personalized exterior wall and ceiling color space, and is an ideal material for architectural styling. Whether it is a multi-functional large building or a unique and innovative new building, it can always meet the different requirements of modern and classical architectural styles, making the building more colorful.

Surface Coating

PVDF color coated aluminum coil

PVDF color-coated aluminum coils are made of PVDF coatings from well-known brands such as PPG, VALSPAR, NIPPON, etc., which are coated on both sides or three layers and baked at high temperature to form a cured coating with a thickness of 25-35μm. Since PVDF coating has corrosion resistance, high weather resistance, strong adhesion, high self-cleaning ability and maintenance-free, aluminum coated coil can keep color fast and durable for 10-15 years.

PE (polyester) coating is a UV resistant coating. According to the coating gloss, it can be divided into matt and high gloss. The dense molecular structure makes the lacquer glossy and smooth, which ensures good printing on the panel surface. Comes with a 7-year weatherproof warranty.

Main Feature

1. Good temperature resistance

The melting point of aluminum is 660 degrees, and the general temperature cannot reach its melting point.

2. Environmental protection

It is not easy to turn yellow, and the chromium-free treatment solution is used to make up for the defect that the film-coated board is easy to change color; the roller coating contains active chemical molecules, which promotes the formation of a protective layer on the surface of the material. The active chemical molecules are stable, easy to recycle and meet the environmental protection requirements.

3. Corrosion resistance

Due to its dense surface oxide film, it has strong adhesion, oxidation resistance, acid resistance, alkali resistance, corrosion resistance, decay resistance and UV resistance.

4. The color is uniform, durable, and the color is uniform and delicate

Soft and colorful, avoiding the individual color difference of traditional spraying, no matter how big the ceiling is, its color and color are consistent. Durable and new.

5. Rigid joint, the strength of the board is extremely high

Combination of rigidity and toughness for free cutting, cutting, arcing, balancing, drilling, joint fixing and edge compression molding.