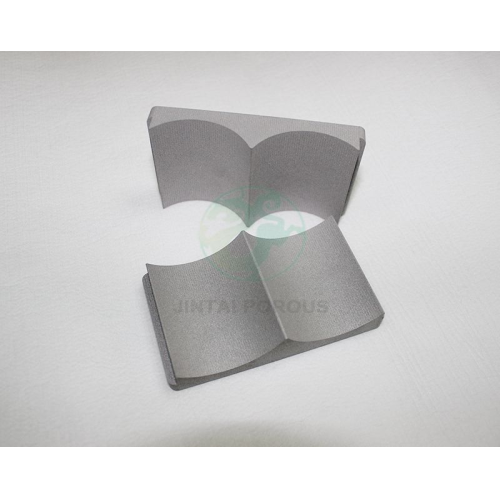

Porous Mould Steel Material

Porous Mould Steel Material is a kind of mold steel with exhaust function launched by Jintai Company for plastic molds, injection molding machines, die-casting machines and other application fields

Product Description

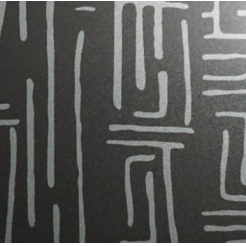

Porous mold steel is a kind of mold steel with exhaust function launched by Jintai Company for plastic molds, injection molding machines, die-casting machines and other application fields. There are a large number of three-dimensional interconnected holes randomly distributed inside the porous mold steel, so the mold steel has good air permeability, which can ensure that there is no residual gas in the product, reduce internal defects, and can reduce the injection pressure, reduce the cycle time,and the weight of the mold can also be reduced. Porous mold steel can improve product quality and save energy, so it has broad application prospects.

Features

Good exhaust performance;

The aperture size can be selected;

The shape and structure can be customized;

Accurate mold size;

Higher hardness.

Injection mold steel

Transmission shaft cooling and exhaust

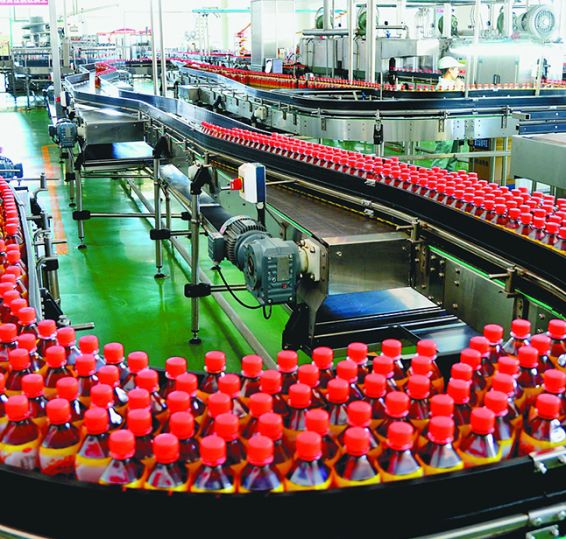

Typical Application