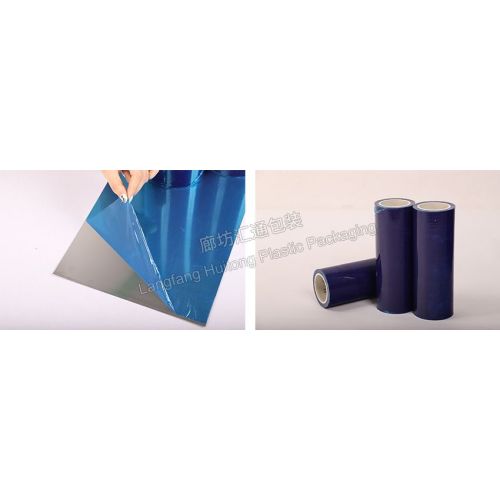

Surface Protective Film

Product Description

https://www.htwrappingfilm.com/products/sheet-protective-film.html

Description

Sheet protective film is based on PE polyethylene film, coated with silicone glue on one side and fitted to the release film. Used to protect sheet metal, aluminum plate, stainless steel plate, color steel plate, glass, PC plate, PVC plate, pp plate, wood plate, baking paint plate and other sheets.

Features:

1) Such products have suitable bonding strength for various pasted objects such as metal, plastic, glass, etc., and have good holding force performance;

2) The surface of the protective film is smooth and flat;

3) Excellent heat resistance;

The application field:

1) Die-cutting protection and re-pasting of conductive cloth;

2) Protection of the shipping surface;

3) Temporary transfer and fixation of electronic products;

4) The protective film has different viscosity, and can be used as a support carrier for foam die-cutting of different thicknesses;

5) The viscosity is divided into high, medium and low viscosity.

The performance parameters of sheet protective film

Sheet protective film is a type of plastic film that is used to protect various types of sheets, such as metal sheets, glass sheets, and plastic sheets, during manufacturing, transportation, storage, and installation. The model and performance parameters of sheet protective film can vary depending on the specific application and the requirements of the user. Some of the key factors that can influence the model and performance of sheet protective film include:

Material: The material of the protective film plays a key role in its performance and durability. Some common material used for sheet protective film is polyethylene (PE).

Thickness: The thickness of the film can affect its strength and resistance to punctures and tears.

Adhesive strength: The adhesive strength of the film is an important factor in its ability to stay in place and protect the sheet from damage.

Elasticity: The elasticity of the film can affect its ability to conform to the surface of the sheet and provide a consistent level of protection.

Transparency: The transparency of the film can be important in some applications, such as when it is used to protect clear sheets of glass or plastic.

Temperature resistance: The temperature resistance of the film can be important in some applications, such as when it is used to protect sheets that will be exposed to extreme temperatures.

UV resistance: The UV resistance of the film can be important in some applications, such as when it is used to protect sheets that will be exposed to direct sunlight.

Durability: The durability of the film is an important factor in its ability to provide long-lasting protection for the sheets.