ball vs butterfly valve

Product Description: Ball Valves vs

Product Description

Product Description: Ball Valves vs. Butterfly Valves

Unlock Superior Flow Control: Choose the Right Valve for Your Needs

In the world of industrial applications and fluid control systems, selecting the right valve is crucial for optimal performance and efficiency. We proudly present a comprehensive comparison of two high-performance valve types: Ball Valves and Butterfly Valves. Each has unique specifications, advantages, and applications tailored to meet diverse needs. Let’s explore these essential components that can transform your operations.

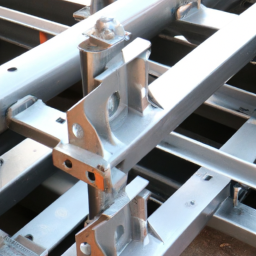

Ball Valves: Precision and Reliability

Specifications:

- Size Range: Available in sizes from 1/4” to 12”

- Pressure Rating: Up to 300 PSI

- Temperature Range: -20°F to 300°F

- Body Material: Stainless Steel, Brass, PVC

- Connection Types: Threaded, Flanged, Welded

Key Advantages:

- Superior Sealing: The ball valve’s tight seal ensures no leakage, providing maximum shut-off capability.

- Full Flow: Its design allows for a straight line through the valve, minimizing turbulence and pressure drop.

- Durability: With fewer moving parts, ball valves exhibit exceptional longevity and lower maintenance requirements, making them ideal for high-demand environments.

- Fast Operation: Quick quarter-turn operation facilitates swift adjustment in flow control, perfect for emergency shutdowns.

Applications:Ball valves are the preferred choice for critical applications, including oil and gas, chemical processing, wastewater management, and HVAC systems. Their ability to handle high-pressure scenarios makes them essential in safety and reliability-focused industries.

Butterfly Valves: Efficiency and Versatility

Specifications:

- Size Range: 2” to 48”

- Pressure Rating: Up to 150 PSI

- Temperature Range: -40°F to 250°F

- Body Material: Ductile Iron, Stainless Steel, PVC

- Connection Types: Wafer, Lug, Flanged

Key Advantages:

- Compact Design: The lightweight and compact structure of butterfly valves saves space, making installation in tight environments easier.

- Energy Efficient: Offers reduced flow resistance, leading to lower energy consumption over time.

- Fast Operation: Quarter-turn operation enables rapid control over fluid flow, crucial for dynamic applications.

- Cost-Effective: Generally lower in price compared to ball valves, providing an economical solution without sacrificing performance.

Applications:Butterfly valves are widely used in applications such as water treatment, food and beverage, HVAC, and pulp and paper industries. Their adaptable nature and ability to handle large flow rates make them suitable for various scenarios, from simple to complex systems.

Making the Right Choice for Your System

When deciding between ball and butterfly valves, consider your specific application needs, including pressure, flow characteristics, and space limitations. Ball valves provide exceptional sealing and pressure capabilities, making them optimal for critical applications. On the other hand, butterfly valves offer versatility, space-saving design, and cost-effectiveness for a range of fluid systems.

Why Wait? Elevate Your Fluid Control System Today!

Investing in the right valve is key to enhancing your operational efficiency and reliability. Browse our collection of high-quality ball and butterfly valves today to discover the perfect fit for your requirements. With our expert guidance and commitment to quality, you can ensure long-lasting performance and peace of mind.

Take the first step toward superior flow control—order now and experience the difference!

Related Products:ball vs butterfly valve, Control valves for petrochemical refining